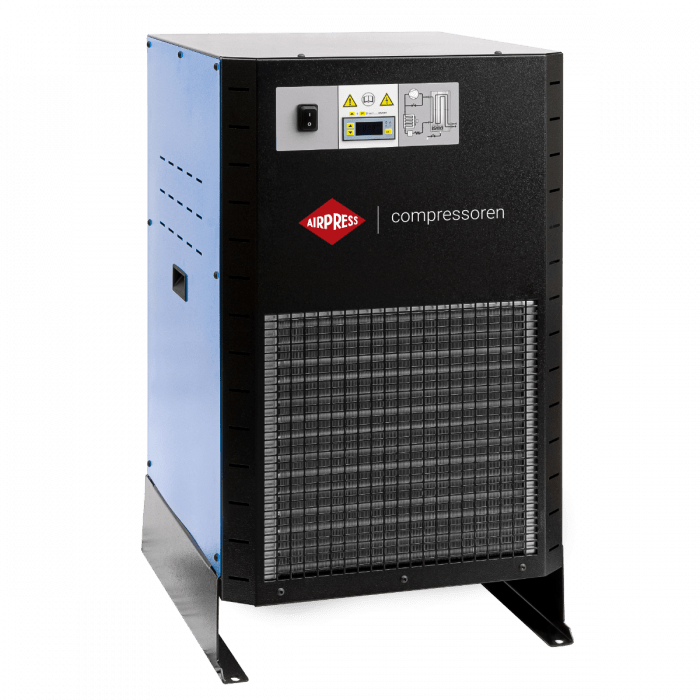

Compressed air dryer RDO 600 2" 10000 l/min "Zero-loss" automatic condensation drain

RDO 600 2" 10000 l/min 16 bar refrigerant dryer is an efficient device for large pneumatic systems. It offers a PDP dew point of +5°C and a 3-stage drying system, eliminating moisture and protecting installations against corrosion, deposits and failures in demanding industrial environments.

- Airpress delivers from our own stock!

- Need advice? Contact us!

- Thanks to our knowledge, you have the best product.

- More than 60 years of experience in compressed air technologies.

Product details

| SKU | 3900600-E |

|---|---|

| EAN | 8712418423167 |

| Length (mm) | 491 |

| Width (mm) | 708 |

| Height (mm) | 973 |

| Weight (kg) | 110,00 |

| Air flow at 7 bar (l/min) | 10000 |

| Air flow at 7 bar (m3/h) | 600 |

| Air connection (") | 2 |

| Connection type | Female |

| Maximum pressure (bar) | 16 |

| Voltage (V) | 230 V / 50 Hz / 1 Ph |

| Power (kW) | 1.3 |

| Cooling air volume (m3/h) | 2200 |

|---|---|

| Refrigerant | R513A |

| Refrigerant weight (kg) | 1.59 |

| Control panel | Digital |

| Pressure dew points (°C) | 3 |

| Max. inlet air temperature (°C) | 55 |

| Minimum ambient temperature (°C) | 1 |

| Maximum ambient temperature (°C) | 45 |

| Purity class - humidity (ISO 8573-1) | 4 |

| IP classification | IP65 |

| Heat rejection (kW) | 4.9 |

| Noise level dB(A) (0 m) | >65 |

| Type | RDO |

Description

RDO 600 2" refrigeration dryer 10,000 l/min 16 bar

RDO 600 2" 10000 l/min 16 bar refrigeration dryer is an advanced device designed for large industrial plants and extensive pneumatic systems. Thanks to PDP dew point +5°C b> and a 3-stage drying system, the device ensures effective moisture separation, protecting installations against corrosion and costly downtime. This reliable solution increases work efficiency pneumatic systems and extends their service life.

Key features

- Class 4 humidity class: Meets the requirements of ISO 8573-1, providing the highest quality air.

- 3-stage dehumidification system: Ensures effective cooling, moisture separation and secondary heating of exhaust air.

- Energy efficiency: Minimizes energy loss by pre-cooling the intake air with dry exhaust air.

- Stainless steel heat exchanger: Guarantees corrosion resistance and long service life even in difficult operating conditions.

- IP 68 protection class: Provides full protection against moisture, water and dust, enabling work in demanding environments.

- Automatic condensate drain: The electronic system eliminates the risk of compressed air loss, ensuring continuous and maintenance-free operation of the device.

Applications

The RDO 600 2" 10,000 l/min 16 bar refrigeration dryer is an ideal solution for large pneumatic systems used in pneumatic transport, production lines, CNC machines and other applications requiring stable and effective air drying.

Technical specifications

- Model: RDO 600

- Nominal flow: 10000 l/min

- Maximum pressure: 16 bar

- Dew point: +5°C

- Ambient temperature range: 1°C – 45°C

- Connection: 2"

Advanced dehumidification technology

The RDO 600 dehumidifier uses a 3-stage heat exchanger that optimizes the moisture separation process. Pre-cooling the inlet air with dehumidified exhaust air increases energy efficiency and minimizes energy loss. Secondary heating of the exhaust air eliminates the risk of water vapor condensing outside the installation, which makes the device extremely effective in difficult industrial conditions. Automatic condensate drain ensures continuous operation and minimizes the need for maintenance.

Ecological and durable solution

The RDO 600 dehumidifier uses R134a refrigerant and a heat exchanger made of stainless steel, which guarantees resistance to moisture and minimizes the risk of corrosion. Regular drying of compressed air protects installations from damage and reduces maintenance costs, contributing to the efficient and reliable operation of pneumatic systems.